The FDM and FFF 3D printing processes are two of the most popular technologies for 3D printing. We’ll help you understand the main difference between these and what your options are when it comes to choosing a printer for your needs.

Contents

What are FDM and FFF?

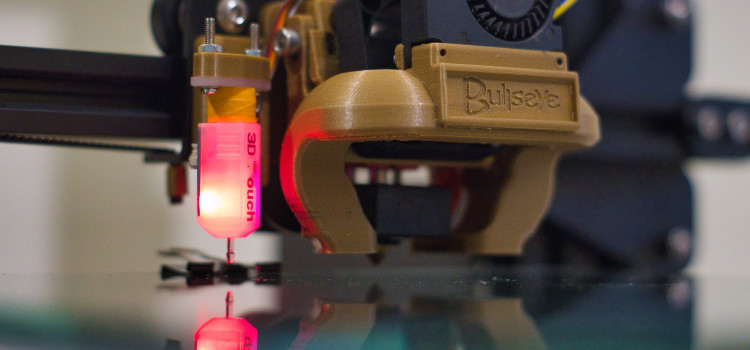

FDM (Fused Deposition Modeling) – Fused Deposition Modeling is similar to the way in which hot glue or melted plastic is extruded. The plastic filament is carried by a small motor that then moves the heated nozzle of extrusion head along its X and Y axis over a moving platform. What’s unique about FDM is that the entire part can be added at once, since the extruder head can make a whole layer in one go.

FFF (Fused Filament Fabrication) – Fused Filament Fabrication is the process of melting plastic filament and then laying it down layer by layer, much like an inkjet printer. The plastic filament is melted in a spool that feeds to the print head. The print head will then move along X & Y axis and will lay down each layer of plastic as it moves over a platform that has been pre-heated to melt the filament.

Pros And Cons Of Each Process

Pros

FDM – FDM allows an entire part to be created at once, and generally provides a stronger and better finished product. FDM is also easier to clean and more cost effective. The extruder head is also less expensive and can be moved from one build plate to the other. FFF requires a heated platform, which adds to the cost of the machine.

FFF – FFF requires a preheated platform which adds to the cost of the machine if it’s not included already with the printer. The heated platform also increases the chance of warping, especially if a glass platform is used. FFF is also much more precise than FDM. Since each layer is printed one at a time, the build plate can be at any angle and any Z height to provide the highest accuracy possible. This makes FFF ideal for even small projects such as jewelry.

Both – Both 3D printing processes are ideal for prototyping, but neither is ideal for mass production. This is because both FDM and FFF printing are time consuming and can be messy. However, this does not mean that their quality and accuracy should be overlooked or ignored. Their strength and durability make them ideal for use in many products.

Cons

FFF – The biggest disadvantage of FFF is that it’s the slower of the two processes. This holds them back from being used for mass production products. Because FFF is a layer by layer process, there may be Z errors that occur when the filament shifts from one Z value to another. This lack of precision also means that there may be warping issues in the final product.

FDM – The biggest disadvantage of FDM is that it can be a messy process. This is due to the fact that the extruder nozzle has to be moved every time a new layer is being added to the build.

FFF Vs FDM – Which One Do I Choose?

This may vary depending on your needs, but there are some general guidelines you should follow:

If you are on a budget or just getting started 3D printing, an FFF printer might be your best bet. They are easier to use and more cost effective.

If you are looking to start a business 3D printing, an FFF printer might be your best bet. They are time consuming, but they are also very precise and allow for better accuracy than FDM printers.

If you want to produce mass market products and have the money for an FDM printer, they can be beneficial. They will allow for fine tuning in order to get the best possible quality and reliability on your production 3D printed parts.

What Materials Do FFF and FDM 3D Printers Use?

The most common materials used in FDM and FFF 3D printing are ABS, PLA, and a variety of other materials.

ABS – ABS is an excellent choice for beginners because it’s relatively easy to use and only requires two types of extruder heads: one for the heated platform and one that melts the plastic filament, like an inkjet printer. Once you have this set up you will be able to create models with lots of detail like those made by CNC machines.

PLA – PLA is easy to use and makes the best choice for beginning 3D printing. It’s a plastic filament made of corn starch that’s similar to ABS which can be used with most FDM or FFF printers. You can easily print models with a large variety of detail, and the material is relatively easy to clean up after each print.

Some Other Options Other Than FFF Or FDM

There are many great 3D printing processes to choose from. While FDM and FFF are the most commonly used, there are some other options that you should consider.

SLA – StereoLithography Apparatus (SLA) is additive manufacturing process that uses a laser to cure photopolymer into a solid object. SLA is cost effective, efficient, and produces high quality parts.

DLP – Digital Light Processing (DLP) is an additive manufacturing process that uses micro-scale light projection to cure photopolymers into solid 3D objects. While it was patented in 1987, it has seen a huge surge in popularity recently.

LOM – LOM or Laminated Object Manufacturing is a 3D printing process used to create objects using a thermoset polymer laminate that’s cured with UV light.

Conclusion

There are many options available to those who want to start 3D printing. The two most popular choices are FFF and FDM which both have their pros and cons.

FFF is the slower of the two processes, but it can be much more accurate and produce better quality parts. This is great for businesses where quality, strength, and durability are needed. These printers will usually use ABS or PLA filaments.

FDM is great for prototyping and mass production parts. The printers are faster and more cost effective than FFF devices, but they can’t produce the same level of detail or strength.

We hope that you have been able to better understand the differences between FFF and FDM 3D printers. If you want to learn more about these two processes, please contact us with your questions and we will help answer them.